Aluminium composite panels (ACP), made of aluminium composite material (ACM), are flat panels consisting of two thin coil-coated aluminium sheets bonded to a non-aluminium core. ACPs are frequently used for external cladding or facades of buildings, insulation, and signage.

ACP is mainly used for external and internal architectural cladding or partitions, false ceilings, signage, machine coverings, container construction, etc. Applications of ACP are not limited to external building cladding, but can also be used in any form of cladding such as partitions, false ceilings, etc. ACP is also widely used within the signage industry as an alternative to heavier, more expensive substrates.

Quality Assurance – 4-POINT CHECKS

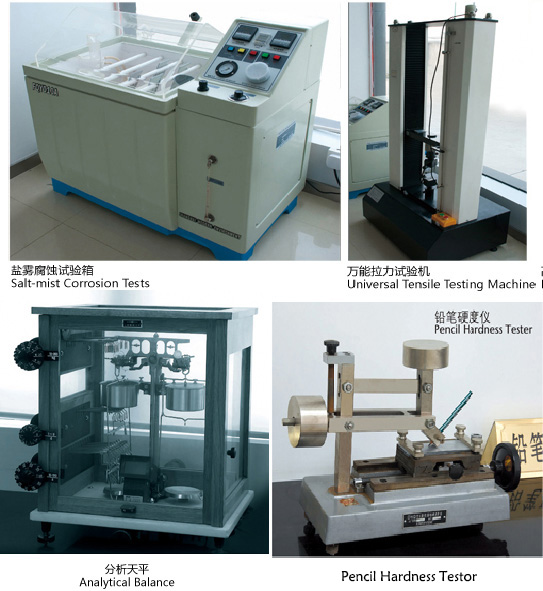

WE FOLLOW 4-POINT CHECKS AT OUR FACTORY FOR QUALITY ASSURANCE :

1. Raw materials check: As soon as the raw materials come into the production units, they undergo tests at our labs to get their properties checked, passing which they go to the store

2. Check at the manufacturing stage: At different stages of manufacturing, tests are done to validate if the purpose of a particular stage has been served or not. For e.g. at the pre-treatment stage it is checked whether degreasing or deoxidizing or chromatizing of the aluminium coil has properly taken place or not.

3. Product check: The product thus manufactured, undergoes the most stringent tests according to global standards, passing which it qualifies for dispatch

4. Post production check: Before being dispatched, visual inspection is done to check product tolerances and any other kind of manufacturing defect.

Alusign Quality Assurance

Under normal weather conditions, the paint on the surface of aluminum composite panel will not peel off, blisters, cracks, or chalking.

Plate peeling and blistering situation will not happen under normal weather conditions.

Abnormal color aberration will not hanppen when the plate is exposed to normal radiation or temperature conditions.

All indicators meet the requirements of national standards and corporate standards or contract requirements, according to the internationally-required inspection methods.